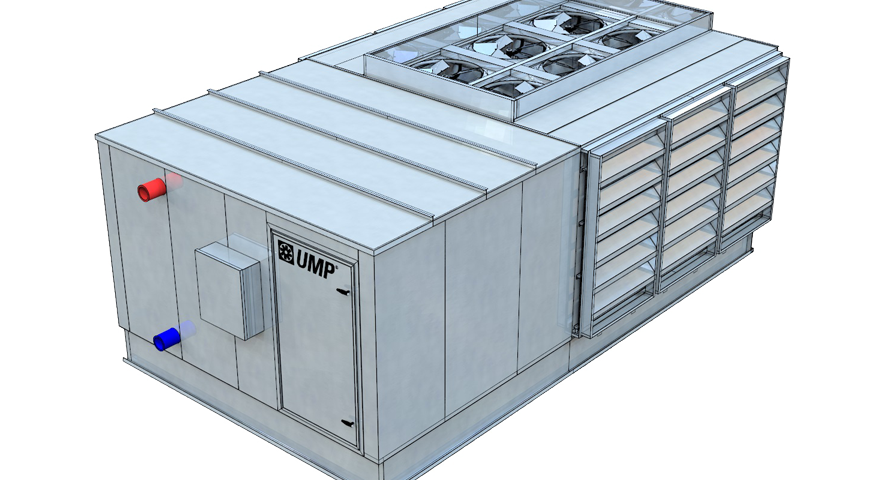

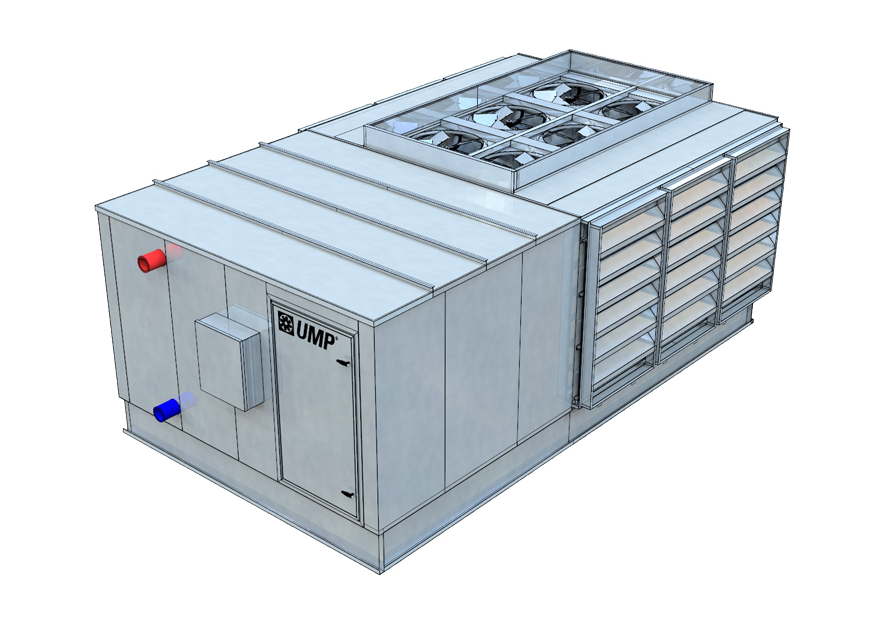

Adiabatic Hydro Cooler

Power usage is one of the main challenges for data center users. By some estimates 2% of all power in the United States is being consumed by data centers and a significant amount of this energy goes toward cooling the data center facility. The Adiabatic Hydro Cooler (AHC) provides an energy efficient, cost effective, flexible, and reliable cooling solution to help data centers achieve an optimal PUE by taking advantage of more free-cooling. For over 30 years United Metal Products has positioned itself as a leading provider of cooling solutions for high density applications. United Metal Products offers an energy efficient, reliable, low maintenance, and cost effective cooling solution using indirect and evaporative cooling technologies in a simple, self-contained unit – the Adiabatic Hydro Cooler (AHC).

The AHC by United Metal Products is specifically designed for data centers that are looking to save money by achieving an optimized PUE. They have been engineered to meet the core cooling needs of a facility, but also are an excellent solution to work in conjunction with traditional chilled water systems. Simply put, the AHC puts economizer strategies on steroids and allows data centers to take advantage of even more free cooling which leads to reduced energy consumption and greater financial savings.